Why does it really matter how the wood is sawn? Rift sawn, Quarter sawn, Flat sawn. It can seem a bit confusing until you break it down. Certain woodworking uses demand certain cuts from a log and can greatly increase the attractive appeal of your projects as well as your success in achieving the correct function.

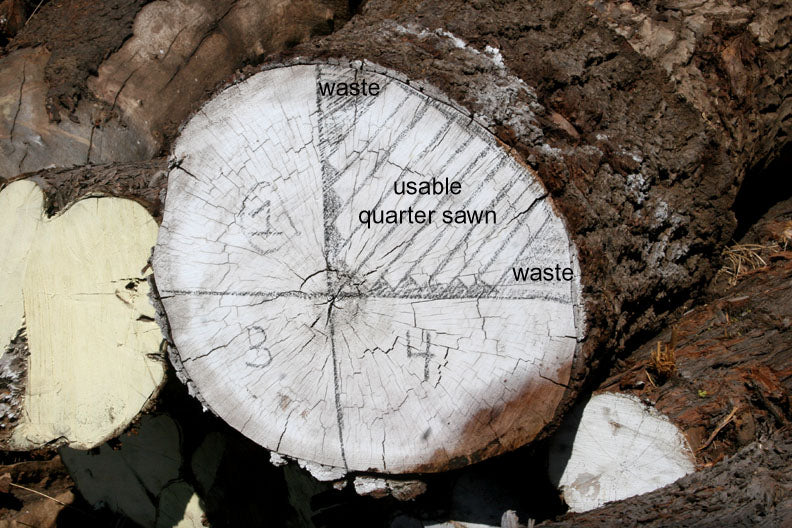

To start with, lets talk about Quarter sawn wood. Quarter sawn lumber is produced by cutting a log into four equal quarters like a carrot when you are making carrot sticks.

Then, you cut each individual quarter so the blade is cutting from the center of the tree (pith) to the bark. About 60% of this is pure quarter sawn and the rest is rift sawn even though it was produced from quarter sawing. About 30-40% of the log is lost in sawdust and edging. The labor for quarter sawing is about 50% more than the other sawing methods as well. So, this is why you can expect to pay up to double the cost for quarter sawn lumber over rift and flat sawn lumber. Quarter sawn lumber has distinct advantages. It is ideal for use in musical instruments such as guitars, ukuleles, mandolins, etc. Musical instrument makers generally need quarter sawn lumber forgood acoustic properties and strength.Quarter sawn lumber shrinks and expands the least out of all of the lumber cuts. Additionally, quarter sawn wood warps, twists, and cups the least of all the cuts, making it the most dimensionally stable. Because of this, it is highly favored in furniture use. Certain species that have interlocked grain and are quarter sawn can produce stunning ribbon figure. Likewise, fiddleback shows up the best in quarter sawn lumber. Interestingly, burl does not show up very well when quarter sawn.

Flat sawn or slab sawn wood is the next choice in woodworking. For more economical and larger cuts flat sawn wood fits the bill very well. Flat sawn wood shows a football type pattern with the grain on the faces. This is generally the least expensive cut in lumber as logs produce more wood from cutting them this way so there is better yield for the mill and hence a lower price for the customer. However, premium wide flat sawn boards can be used for table tops, bar tops, and counters. These are unique as there are usually only 1to 4 boards out of a log that are suitable for this. These arecut roughly half way between the center of the tree(pith)and the bark. If they are cut too close to the bark the board will cup severely. Ifthey are cut too close to the heart the board willsplit down the middle. Expect to pay a 30-40% premium for the best boards of the log especially if the wood is well figured. Depending on the type of figure, flat sawn lumber can show extremely beautiful grain, making it an exceptional choice in woodworking. Pomelle and Quilted figure only show on the flat sawn face. Exceptional burl eyes show the best when flat sawn.

Riftsawn is a great compromise between the two cuts and is only slightly more expensive than flat sawn lumber. The faceslooklike quarter sawn boards withwider lines. These boardsare less likely to move during drying and use and there ismuch less waste in cutting the log into saleable lumber. Also, you get most of the structural/dimensional stability of quarter sawn lumber and the edges of the boards also appear quarter sawn. Furthermore, rift sawn boards are available in wider widths than quarter sawn lumber typically. Fiddleback, quilting, pomelle, and burl do not show up as well on the rift sawn face. However, it still shows and can yield unique and very beautiful patterns & colors.

For the best wood at the best cost consider purchasing "mill - run". This is unsorted and contains all three cuts. The millcan sell the whole log or a good percentage of it so you end up with some quarter and rift sawn boards ata price slightly higher than flat or slab sawn lumber. In this scenario, you would need to expect a mix of sizes from 4" up to generally 12" wide inspecies such as Maple or Myrtle wood for example with most of them in the 7-10" wide range.

So, when you break it down, there really is quite a difference between the three cuts of wood and the final product you can achieve when working with them.